Just Big Enough Competition

Boiler House

The former Boiler House for the historic Clarke School for the Deaf, this solidly-built masonry building had fallen out of use many years prior to renovation. It was carefully cleaned and a 2nd interior floor was added. Large ground floor and arched second floor window openings were preserved with new efficient windows in their place. This project exemplifies how a bright, open modern interior spaces can fit within the historic context of the traditional New England school buildings and campus.

The tall interior space, once home to steam boilers that heated the entire campus, now hosts a second floor with wood stairs and a custom designed metal handrail to the buildings upper two units. Light fills the new apartments through the new operable energy efficient windows.

Building on our expertise rehabilitating historic buildings with modern efficient building envelopes, TDA negotiated local, state & national historic reviews to help this renovation earn Historic Preservation Tax Credits. The completed building is one of a half dozen other buildings from the campus that TDA has helped to renovate for residential and office uses.

236 Pleasant Street

Thomas Douglas Architects investigated the possibilities for a small lot at the edge of a busy downtown district. The program included ground floor retail and studio space, with residential units on the upper floors.

The articulated facade accentuates an adjacent bend in the road and creates a visual landmark for those traveling either direction. A combination of double hung and storefront windows are separated by a strong horizontal element, highlighting the divide between the residential and commercial uses.

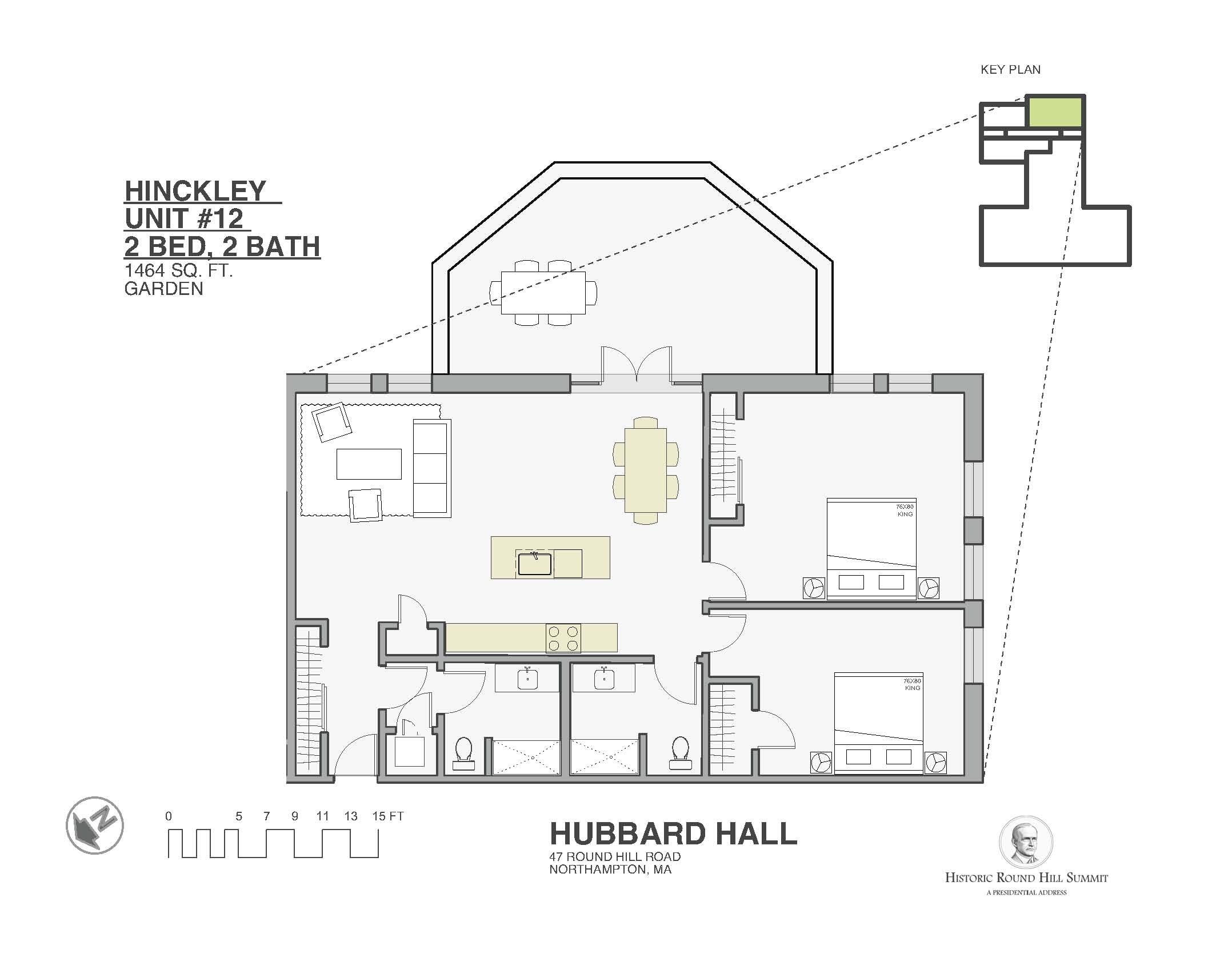

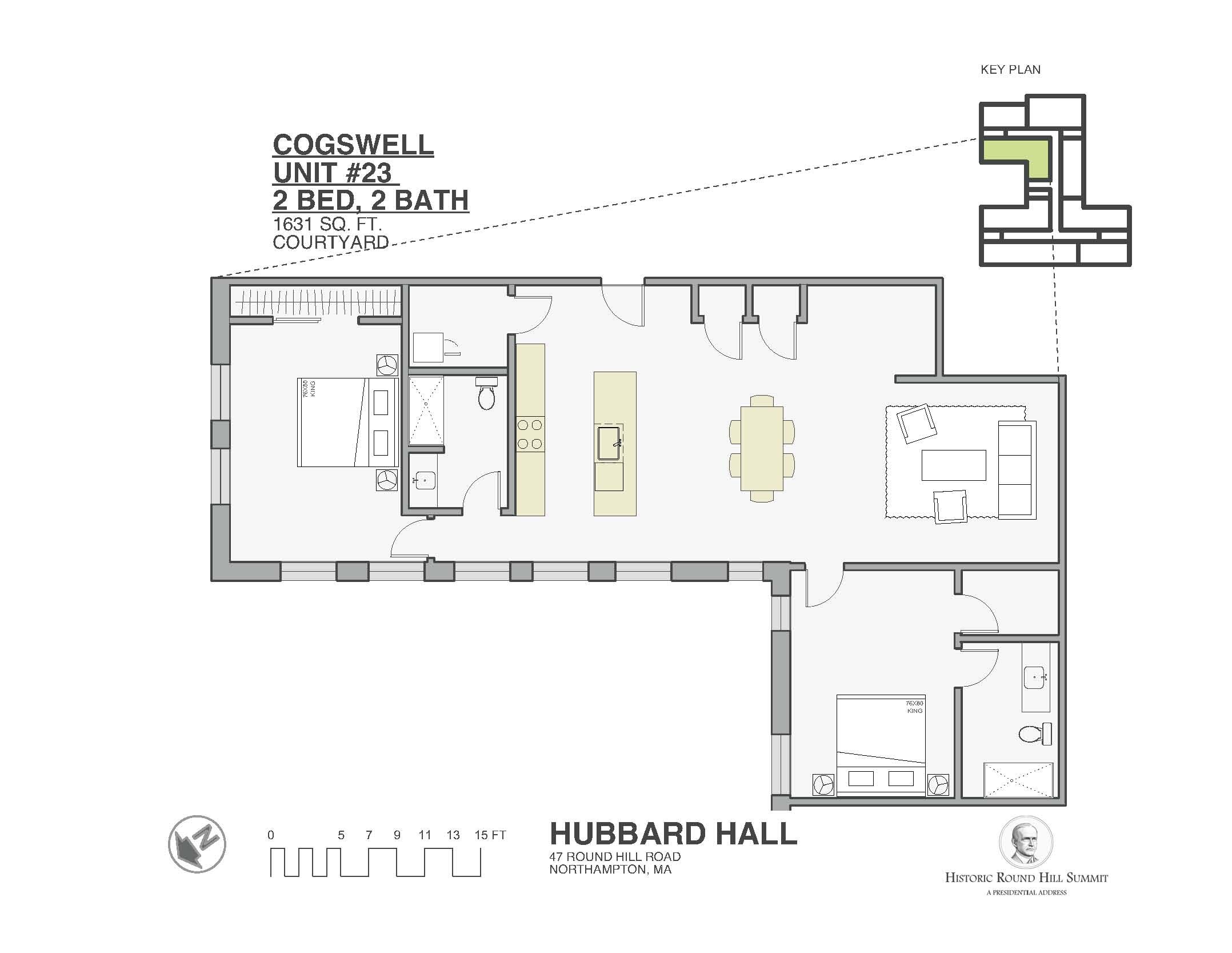

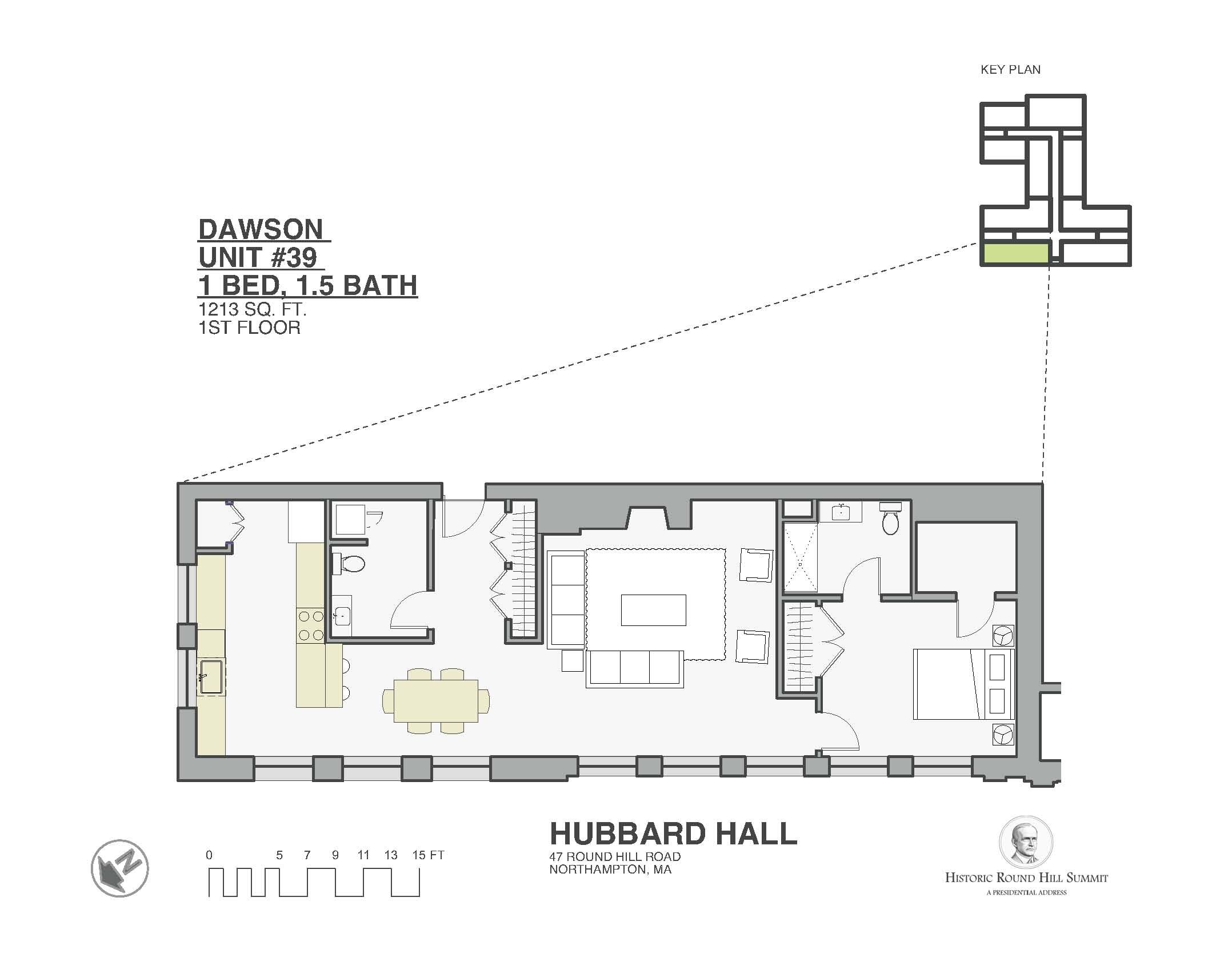

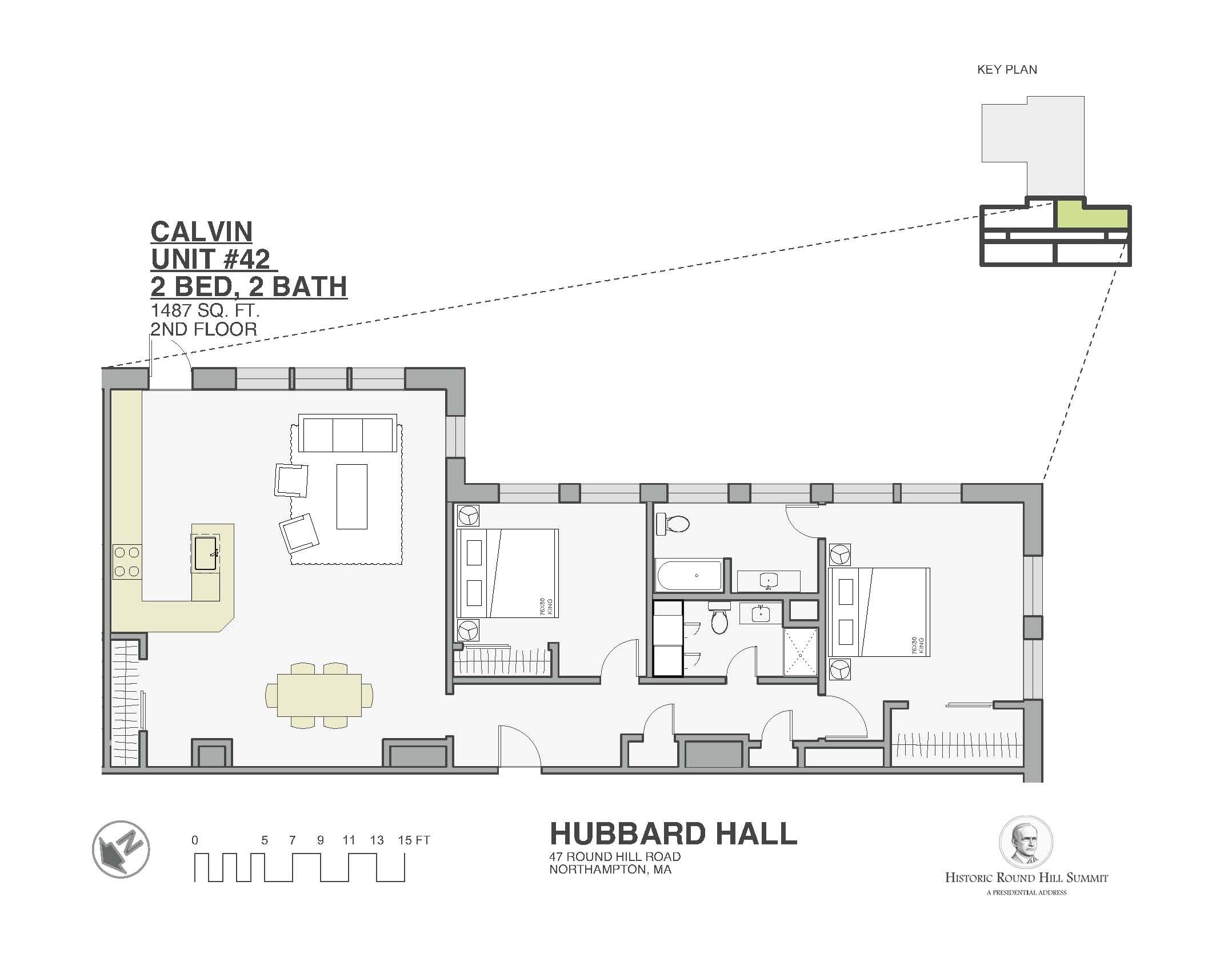

Hubbard Hall

A 1920s administrative and classroom building at the historic Clarke School for the Deaf, Hubbard Hall’s high ceilings and generous windows have been repurposed as high-end residences. Perched atop Round Hill overlooking downtown Northampton, these luxury apartments boast original historic details, restored and new hardwood floors, fireplaces and upmarket modern amenities.

The historic masonry building received new insulation at all exterior walls and new double pane windows. Finish materials and HVAC equipment were selected carefully for efficiency and reliable performance.

Sustainable features

Energy Efficiency:

Very high insulation values in walls, roof and foundation

Double pane energy efficient windows

Airsealing details

Energy recovery ventilation

Digital controls in each room control the heating system.

Window are used to get natural daylight into as much of the building as possible

Materials:

All paints & finishes used are low- or no-VOC (volatile organic compounds).

Locally sourced wood and stone

Smith College Conway House

The Conway House sits back from the road close to downtown Northampton, protected from traffic and surrounded by trees. This new construction was built to provide apartments for non-traditional Smith College students, some with families. The three story, 13,000 square foot building has ten two bedroom apartments, one of which is fully accessible, and several common areas for laundry, storage and socializing.

The building is super-insulated and has large insulated triple-glazed windows that allow for plentiful daylighting but limit energy loss. Interior finishes were chosen for their natural durability, beauty and environmental integrity - natural resilient flooring, Green Seal certified carpets and low VOC paints, adhesives, and composite materials. Additionally, the building used an energy recovery ventilator to conserve energy as the fan ventilates the house.

Sustainable Features:

Energy Efficiency:

Very high insulation values – R-48 & R-56 Walls, R-70 ceiling (attic)

Very high performance windows – all fiberglass construction, triple pane glass (R-7)

Air tight detailing used extensively (Note: the building was “blower door tested” by Energy Star technicians reaching a level of tightness 3 times lower than minimum)

Constant volume ventilation with energy recovery has been installed to maintain a fresh air supply. (This system continuously exhausts air from the bathrooms while fresh air is supplied to the corridors. Heat & moisture energy is recovered with equipment installed in the attic).

Air conditioners, refrigerators and dishwashers are Energy Star rated.

All lighting is compact fluorescent with a very low Watt to lumen ratio. The lamps were provided by the Energy Star program.

Digital controls in each room control the heating system.

Heating is provided by two, wall mounted gas fired boilers located in the lower level mechanical room. (They are modulating boilers, digitally controlled, that will produce heat based on outside air temperature and domestic hot water demand)

Materials:

Wall insulation is made of expanded polystyrene. (The same material disposable coffee cups are made of).

Attic insulation is blown cellulose treated with boric acid.

All paints used are low VOC (volatile organic compound) or no VOC.

Marmoleum floors were installed in kitchens, baths and corridors (no vinyl’s used) Marmoleum is made from primarily natural raw materials; linseed oil, rosins, and wood flour, calendered (pressed) onto a natural jute backing.

Rubber base was used in the kitchen and bathroom not vinyl.

Carpeting is made of nylon, constructed and installed using very low VOC glues.

A few other notes:

The ceilings were raised higher than most residential buildings to accommodate a third sash. With taller windows, natural light can penetrate deeper into the rooms. Mini blinds were installed for best control of natural light and privacy.

The buildings heating system is designed to accommodate the addition of solar thermal panels in the future.

Conway Street School

TDA worked with the owner/developer to transform an abandoned early 1900’s elementary school building into twelve apartments with very high energy efficiency. This project transformed a derelict building into one of the more iconic and desirable properties in town.

The structure of the three story, 4500 square foot masonry building was in excellent shape, allowing the team to completely gut the interior and begin the redesign with ample freedom also while maintaining the historic character of the building’s exterior.

The reimagined design takes advantage of the tall windows and high ceilings to create spaces that are airy, light and dramatic. The second floor units each have an upper floor while the even the basement units have plenty of light and space. The entire project has an emphasis on energy conservation and efficiency features.

Sustainable features

Energy Efficiency:

Very high insulation values in walls, roof and foundation

Triple pane energy efficient windows

Airsealing details

Energy recovery ventilation

Digital controls in each room control the heating system.

Window shading from solar hot water system

Window and skylights are used to get natural daylight into as much of the building as possible

Materials:

All paints & finishes used are low or no VOC (volatile organic compounds).

Locally sourced wood and stone

Interior finishes were chosen for their natural durability, beauty and environmental integrity

30 Olive

TDA worked with the owner to transform this 1920s former mill building, located just down from the center of the city, into a modern apartment building while preserving signature interior details and historic exterior features.

The energy efficiency of the building envelope was improved immeasurably through careful airsealing and insulating, new windows, a new well-insulated roof and solar panels for both hot water and electricity generation.

Sustainable features:

Energy Efficiency:

Very high insulation values in walls, roof and foundation

Air tight detailing used to prevent energy loss

Heating and air conditioning use energy recovery

Day lighting strategies are used to get natural lighting into the deep interior spaces.

Photovoltaic and solar hot water arrays

Materials:

Interior finishes were chosen for their natural durability, beauty and environmental integrity, locally sourced whenever possible.

180 Earle Street

Smith College and Economic Resources for Women (HER Inc.) formed a partnership to build this new 10,000 square foot house. The building contains 16-single room occupancy units, each with individual kitchenettes and bathrooms. The first floor has a 2-bedroom manager’s apartment as well as a common living room, conference room and laundry room. The building has accessible units and uses green materials like concrete board siding and linoleum flooring. The majority of on-site trees were carefully saved and all storm water runoff was retained on site. The building designed to use energy efficiently and sustainably and received EnergyStar certification.